If you follow the Pearl River west from Hong Kong, you float through Guangdong province, home to 80 million people. At the conflux of the Xi River, the province of Guangxi is home to another 48 million people in a half dozen cities. There, outside Guigang, above the Yuji Forest, are three massive, 8-story buildings, with another under construction just below. As you come up the road, you might think it’s a Vegas-sized resort being built on the red dirt hillside. Which it sort of is — just for piglets, not people.

High-rise pig farm in Guangxi province, China. Credit: Thomas Suen/Reuters

Where land is scarce and the population is booming, “pig city,” as it’s being called, has become a focal point for the challenge of feeding the world’s growing demand for protein. Every year, all around the globe, 140 million people join the world’s middle class and are able to afford more meat. In China, the average consumption of meat per person was 30 pounds in 1980; today, it’s 140 pounds – and there are an additional 300 million people.

Pig City’s complex was built with southern China’s population in mind. At full capacity, it will produce 840,000 piglets a year, making it the world’s biggest farrowing operation. Manure is piped from the building for separation into fertilizer for the sugarcane, peanuts, and cotton grown in the province’s river valleys and terraced hillsides. Biosecurity for the pigs was another primary reason for going vertical; outbreaks of African swine fever and blue ear disease have inflamed public concerns, and decades of heavy-metal mining contaminated 19% of China’s farmland. The Xi River, in places, is purple from textile factory runoff, and pockets of the Pearl are hypoxic dead zones.

It’s a misnomer that everything is cheaper in China. Depleted soil, and lack of clean water – combined with less efficient farming practices – compound the challenge. Just the cost of pig feed, to gain the same weight as an American hog, is net 77% higher in China.

By 2050, the world’s population will increase by 2 billion – a gain of 25 percent. But with people demanding more protein, our food system has to grow far more than 25%. Animal protein is governed by “feed conversion ratios” – for every pound the animal gains in weight, it has to consume several pounds of feed. The United Nations has projected that to both feed the growing population, and to satisfy its demand for protein, output from the food system must increase at least 70% by 2050.

But if we already have to stack the piglets 8 stories high, this seems like an impossibility. Aren’t we using all the cropland that we can? Where will we get the water to sustain the crops? Won’t all that fertilizer, trickling into our wells and oceans, contaminate the water?

Increasingly, we are hearing cries of an impending Malthusian catastrophe. Since the late 1960s, by shifting to high-yield crops that could be boosted with nitrogen fertilizer, the world has tripled our yield productivity of cereals such as wheat, rice, oats and corn. Intensive livestock practices have resulted in similar efficiencies. Since 1990, the world has added 2 billion more people, but the food system growth has outpaced it; we are producing 17% more food per person than in 1990. Back in 2013 and 2014, there were a number of warnings that agriculture was reaching a yield plateau. But then yields defied those predictions, and there does not seem to be any slowing of this long term growth, in either grains or livestock. This is true even in the US and western Europe, which have been using decreasing amounts of fertilizer since the early 2000s.

Though these growth trends provide some reassurance, it’s natural to want more detail, to want a glimpse of the future. What technologies, and what farming practices, will fuel this next generation of growth?

Let’s break this down into two categories. One category is the further dissemination of existing technologies and practices, into areas that are still very inefficient. The second category is new technologies, just emerging, that are very promising.

One of the greatest causes of dense urbanization around the world is the inability of smallholder farmers to compete at prices driven down by industrialized farming. Families are forced to sell or abandon their farms and move to the cities for a different way of life. Today in China, 28% of the population works in agriculture; a decade ago, it was 39%. This is happening all over the developing world—in Brazil, it’s fallen from 16% to 10% in a decade. In Indonesia, 40% to 32%. The losses are precipitous—but not unstoppable. For the most part, these small farms just need to adopt better practices. The difference that can make is staggering.

The United Nations’ Food and Agriculture Organization did a meta-analysis of 286 farming intervention programs, across 57 countries – which, together, have been put to work on 3% of all the cropland in the developing world. Those programs averaged a 79% gain in yield, and a 71% reduction in pesticide use. These practices were not high-tech–they include using modern hybrid seeds bred for consistency and productivity, with erosion control, reduced tillage, tree planting, livestock integration for natural fertilizer, water conservation, and aquaculture in rice paddies. These interventions work — it’s paramount to expand them from 3% of the land to the rest.

Then this bounty has to make it to the market – without being lost to pests, spoilage, or mishandling. Today, one third of food grown on small farms doesn’t make it to market in developing countries. Low-tech solutions make a big difference, such as small metal silos and using crates rather than sacks. Mid-tech solutions involve low-cost solar-powered refrigeration systems at the village level.

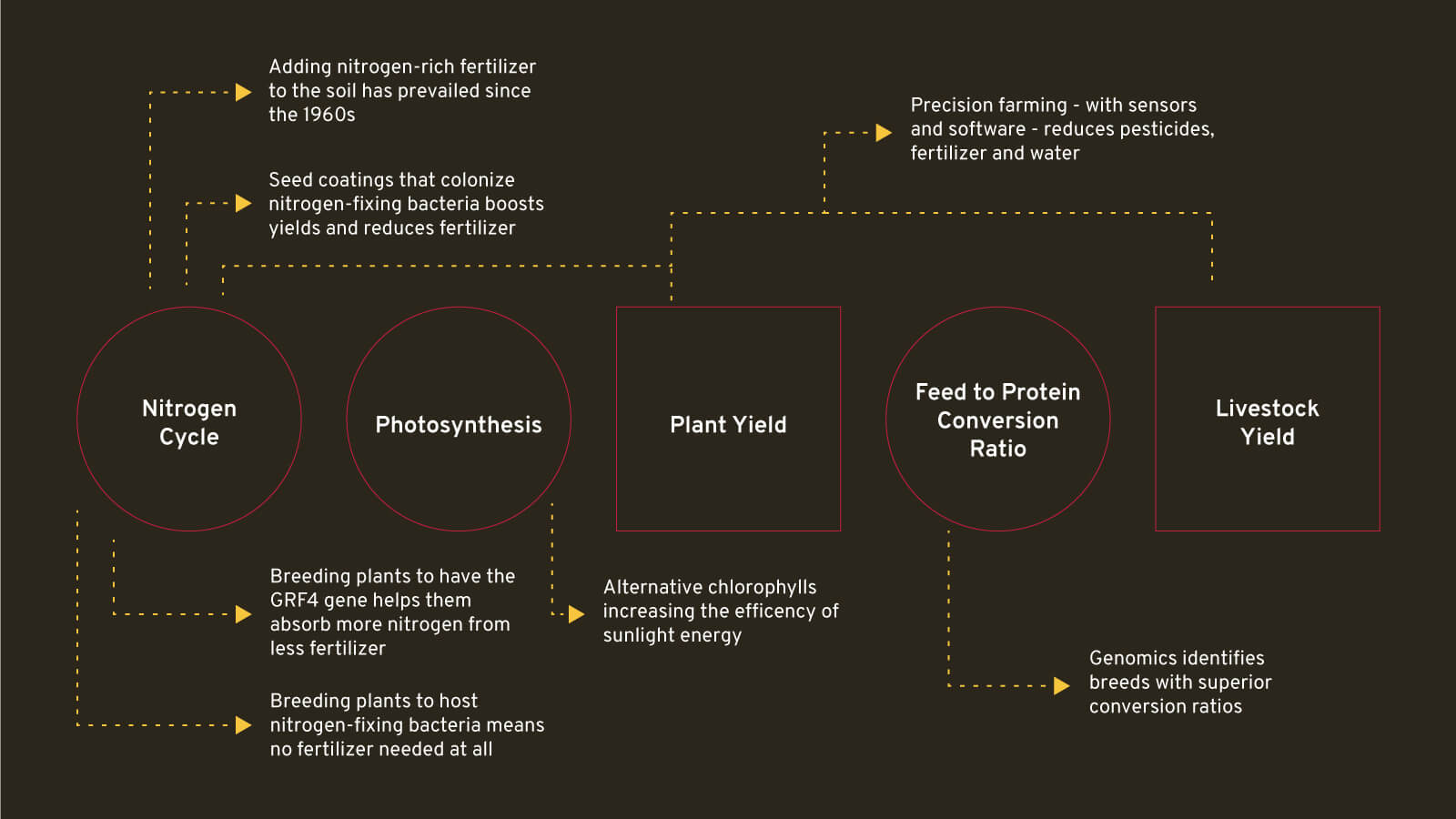

Many new technologies focus on the nitrogen cycle essential to plant growth. Adding synthetic fertilizer to soil is nothing less than a hacking of photosynthesis—but there are many new ways to hack it, while reducing or eliminating fertilizer. One discovery is the genes that code for “growth-regulating factor-4,” or GRF4. GRF4 increases a plant’s ability to absorb and metabolize nitrogen. By cross-breeding new strains of grains that have more GRF4, scientists are creating non-GMO plants that grow very rapidly, using very little fertilizer–but absorbing far more of it.

To be available to plants, nitrogen from the air has to be “fixed,” which means it’s converted to ammonia or nitrogen oxide. Most plants can’t do this at all; and in those that do, such as legumes and peanuts, it’s not actually being done by the plant. Rather, it’s a bacteria inside the plant roots that fixes the nitrogen. This understanding has led to two new approaches. Indigo, an ag-tech company from Boston, infuses seeds with nitrogen-fixing bacteria inside; once in the ground, this bacteria colonizes inside the plant and in the soil, which enhances the plant’s ability to extract nutrients from the soil. Their first batch of cotton, from West Texas, showed an 11% yield gain, even in drought conditions.

Another approach is giving more plants the same thing legumes have, a home to bacteria that fix nitrogen themselves. One ancient maize, for instance, oozes a mucus syrup these bacteria feed upon. Genetic analysis at UC Davis has identified the genes that produce the syrup. They are at work now, experimenting on cross-breeding this ability into common crops. If successful, plants wouldn’t need any fertilizer – the bacteria will just pull it out of the air for them.

If you think of a plant leaf as a solar panel, it turns sunlight into a source of energy to power photosynthesis. But it’s surprisingly inefficient — only 3% to 6% of the available energy is converted. That’s because plants only absorb red and blue light at the ends of the light spectrum. Then the plant spends a significant amount of energy dissipating excess heat. Making this process more efficient—by breeding plants to have alternative chlorophylls—has the potential to make plants 50% more productive.

Precision agriculture is the method of using remote sensors and software systems with machine learning to maximize yield while minimizing irrigation, herbicides, and fertilizer. Connected to weather prediction systems, they also alert farmers when to sow their seeds. The cost of these systems has fallen dramatically; we are nearing the point they can be financed even for smaller farms, though government subsidies for farming equipment acquisitions would speed up their adoption. So far, these are showing yield improvements of 5%-40%, and reduce water usage by 20%.

In livestock, sensors allow chickens to go cage-free. In sheep and cattle, they help identify sick animals before humans spot them, reducing the need for antibiotics. They prevent swine from rolling onto their piglets.

Genomics helps identify lines of livestock with exceptional conversion ratios and superior health—in cows, this is called their “Expected Progeny Difference” formula. One of the reason beef production in China is less than half as productive as it is in the US is their reliance on indigenous herds of yellow cattle, rather than Angus and Hereford.

Even with all these methods combining to boost our food system output, it may not be enough on the existing cropland. In search of more land, many countries still allow their precious forests to be razed, even though we know forests are the lungs of the planet.

One amazing possibility is to grow grains in the desert—long considered hostile to agriculture. In the United Arab Emirates, they are planting a variety of “sea rice” that has been bred to tolerate salts; the paddies are flooded with diluted seawater. Scientists have been working on this since the 1970s, and only now have reached a variety with enough yield to make it truly economical. Around the world, there’s a lot of desert with easy access to seawater—386,000 square miles, or more than the state of Texas. If it flourishes, sea rice could feed an estimated 200 million people.

Then there is the possibility of growing indoors—and like Pig City, going vertical. Yields are much higher, but so are the costs. Thus far, it’s only economical for premium lettuce, vegetables and flowers. But the world is also on the brink of an energy revolution; utility-scale solar power has dropped 86% since 2009, and is now cheaper than burning coal for electricity. If it continues to decline, it could usher a new era of indoor agriculture, with plants fed by low-cost red and blue light.

The ultimate form of indoor food is the new field of cellular agriculture. Cellular farmers don’t use dirt, or sunlight; nor do they use plants or animals. Instead, they use bioreactors, yeasts, and microbial fermentation, mimicking the natural processes used inside cells. There are no pests, and not even trace amounts of toxins. They can replicate both the fat cells and muscle cells of bacon; they can make the collagen fibers that give ribs their lip-smacking flavor; they can perfectly replicate the natural sugars in mothers’ breast milk.

Cellular agriculture is a science that is emerging out of the laboratory and seeking to scale to industrial size. Until it’s affordable to engineer muscle cell tissue for consumption, what we’ll see on the market are hybrid products, where a small portion of the product is synthetically manufactured, while the remainder of the product is more familiar — extruded plant proteins, plant fats, and sugars. Plant-based hamburgers, made tastier—today with 2% synthetic soybean heme, tomorrow with 2% synthetic collagen. In proteins from chicken nuggets to ready-to-eat shrimp, only a small portion of the product is providing the signature taste and texture. The rest can be yellow peas run through a shear-cell extruder to have the grain of meat, or algal oils for seafood flavor, or high-protein koji fungus for umami.

Cellular agriculture can also solve bottlenecks in the food sector’s supply chain. For instance, salmon aquaculture is threatened by the rising prices and dwindling supply of fish meal, conventionally made from small, oily forage fish pulled from the oceans. A very promising new technology creates fish meal from a consortium of high-protein bacteria – using nothing but waste carbon dioxide and hydrogen. It’s 100 times more efficient than feeding forage fish to salmon. When it succeeds, it will help restore a natural balance to the world’s overfished waters.

It’s often claimed that the world’s population is just going to have to reduce our protein intake, in order to have enough food for all. While many people have made that decision, and have shifted to plant-based diets, there are many reasons to be hopeful that farmers and scientists—supported by government funding, and cheered on by consumers—will continue to keep the planet well fed.